How I Turned This …

Into This:

Crown International created the long discontinued SASS (Stereo Ambient Sampling System) microphone housing in the late eighties. This strange-looking microphone housing featured the company’s relatively new PZM microphones. Boundary microphones like Crown’s PZM’s were becoming a hit with sound engineers and could be seen at the foot of theater stages, above drum kits, above church choirs and orchestra pits. Simply explained, boundary microphones, when placed against a surface, capture direct and reflected sound at the same time, thereby eliminating some of the inherent problems with placing a traditional microphone on the floor or against a wall. The larger the surface the lower the frequencies the mic can capture. A bonus of having the mic element flush with the boundary is a natural increase in gain without having to add more via your recorder. That’s less self-noise, less hiss and more volume added to the chain free of charge. Creator Michael Billingsley took this concept further. He used two PZM’s, separated by a baffle, to create a convincing stereo sound image.

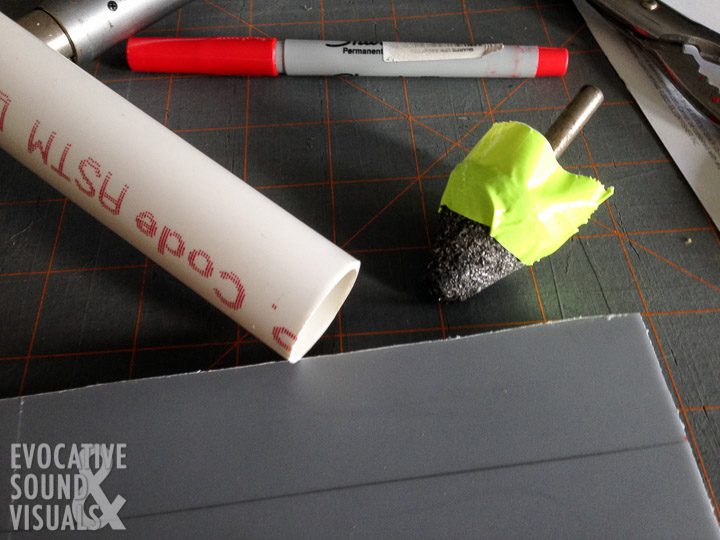

I too used Crown PZM’s years ago when I helped run house sound for a local theater in north-central Ohio. They’re great for louder sounds but a bit noisy for quiet natural soundscapes. Thus nature recordists have taken to modifying existing Crown SASS rigs, which come up on the used market now and again (one sold six days ago on eBay for $615), or have taken to building their own. I, like other creators whose fine work I’ll link to at the end of this post, built my own using low-noise Audio Technica 3032 omnidirectional ‘pencil’ microphones. Instead of using wood or foam as others have, I chose plastic. Isn’t there enough plastic going into landfills? I regretfully added more this morning before sitting down to write this. So why not reuse some of this plastic for good.

Long walks with our dog had me envisioning what it would take to make a professional-looking DIY plastic SASS housing. I settled on the following idea after stumbling upon a vintage Samsonite travel case at a thrift store for $3.00. This is the kind of small, top-handled beauty case that comes with a little compartmentalized shelf, has a mirror on the underside of its lid and smells like your grandmother’s 50-year-old perfume. By its long out of fashion mustard-yellow color, I’m thinking it’s from the late 60s or early 70s. I found a large gray storage tote at another nearby thrift store on that same trip for $1.50. I’m fortunate to have three thrift shops within five minutes of my home. They each seem to specialize in certain goods.

Plastic of course comes in a variety of consistencies and thicknesses. Some are pliable and bend when you want them to, some are brittle and crack if you try to bend them and some do not bend at all. The Samsonite case is the ladder. With walls one-eighth of an inch thick, it took a Dremel tool with a cutting bit to go through it. Just what I wanted to make a durable foundation for the rig.

I took the rig out for its maiden recording voyage over the weekend. While walking out the front door I heard stock cars practicing at the quarter-mile oval track down the road and thought hey, how about that place? A worker who remembered me from last year’s recording visit was kind enough to let me set up right past the first turn approximately six feet from the track. The MP3 snippet below captures one practice lap of a stock car traveling solo, from left to right, around the course. You tell me if the stereo separation is adequate. The recording was normalized but no other filtration was added.

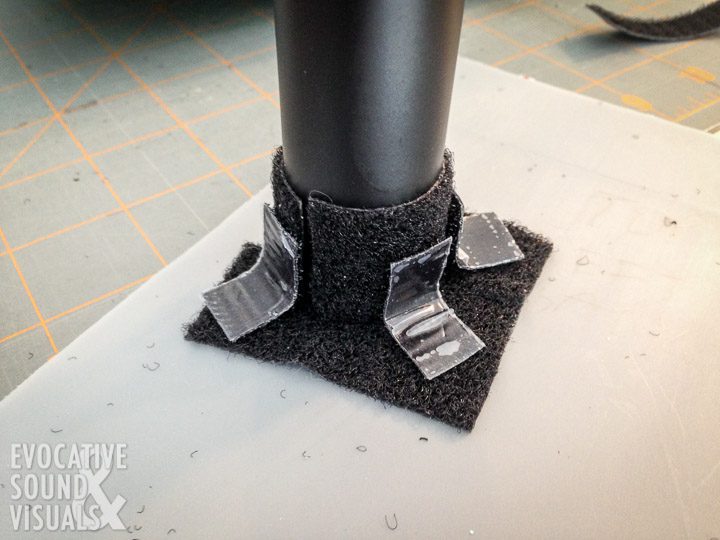

Coming in slightly larger than the original Crown Sass, my DIY rig, at 15 1/4 by 9 1/4 by 7 inches (38.7×22.9×17.8 cm), gives me slightly more surface area around the microphones. I alluded to the positives behind this concept above. It weighs approximately two pounds. I never would have thought plastic and foam and tape would weigh so much. I stayed away from using glue. Instead, I used an ample supply of hook-and-loop fastener tape. That’s Velco for the uninitiated but since I don’t know my tape’s origin I’m sticking with its generic name.

After searching for vintage Samsonite train cases on eBay, I see they’re kind of expensive. Who knew? Used inexpensive alternatives may be plastic file containers, toolboxes, or other small totes. Think rectangular boxes with shallow lids and deep bottoms. Get creative.

There are several ways to record in stereo with omnidirectional microphones. I have used my trusty pair of Audio Technica 3032 mics in other DIY baffled-omni arrays as well as an A/B spaced pair configuration. Each has its purpose. This DIY SASS gives me another option, the goal of which is to help reject sound from the rear that I wish to avoid. I hope you find the step-by-step (more or less) photos of the building process useful. If you have any questions or comments please let me know below.

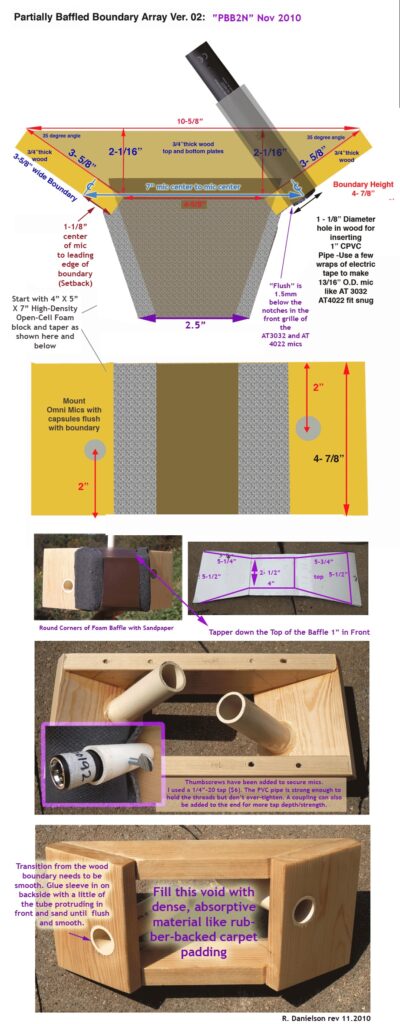

The majority of my design ideas, including microphone spacing, angles and so forth, came from Rob Danielson. Here is his version 2 design from 2010:

This is a good time to mention that this is a really messy and loud process.. The Dremel cutting into an open box creates a lot of noise, and plastic chips fly everywhere. Please wear proper ear and eye protection if you go this route.

A few more photos of the finished product (just because I’m happy with the results):

Further reading:

- Australian nature sound recordist Vicki Poyws has a great explanation on how to make a DIY SASS on her website. She made her ‘SASS-lite’ out of closed-cell foam.

- Tom Benedict created a beautiful wooden DIY ‘Pseudo SASS array in 2015. You can see how he did it here.

- See the specs for the original Crown SASS here.